Electric Steel Elevator

Innovative in 1901, the Electric Steel Grain Elevator complex was obsolete, vacant, and an attractive nuisance 112 years later. We documented the property before it was demolished and developed interpretation to perpetuate its legacy, incorporating a salvaged section of a steel tank.

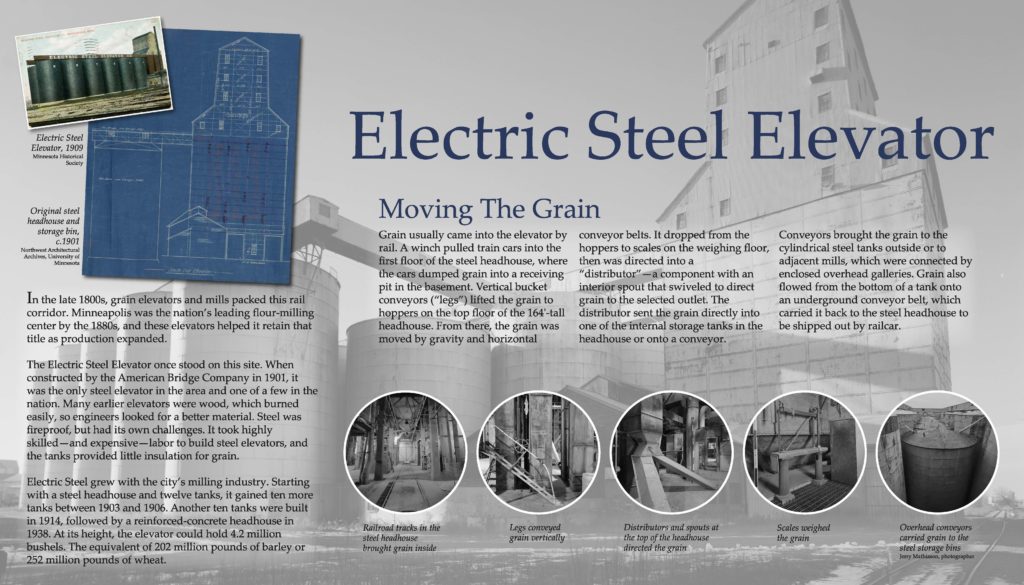

In 1901, a group of prominent Minneapolitans incorporated the Electric Steel Elevator Company. They commissioned a head house and twelve tanks that same year to capitalize on the growing need for grain storage in a burgeoning industrial district along a rail corridor just east of the Minneapolis campus of the University of Minnesota. The circular tanks were arranged in two rows of six, with plenty of space on either side to allow for future expansion. A brick millwright shop, a brick coal shed, and two steel car sheds were also built during this initial construction.

The head house and bins were constructed by the American Bridge Company (ABC) and designed by one of its engineers, C. A. P Turner. J. P. Morgan incorporated ABC in 1900 and it became a subsidiary of the United States Steel Corporation the following year. Over its tenure, ABC acquired twenty-four fabricators and became dominant in the industry. Turner was a nationally prominent engineer and architect who went on to gain additional renowned for his mushroom column and other advancements with reinforced concrete.

The head house and bins were constructed by the American Bridge Company (ABC) and designed by one of its engineers, C. A. P Turner. J. P. Morgan incorporated ABC in 1900 and it became a subsidiary of the United States Steel Corporation the following year. Over its tenure, ABC acquired twenty-four fabricators and became dominant in the industry. Turner was a nationally prominent engineer and architect who went on to gain additional renowned for his mushroom column and other advancements with reinforced concrete.

As the facility’s name indicates, steel formed the head house and bins. The earliest grain elevators were made of wood, but the fire risk hastened a shift to other materials. Between 1899 and 1910, engineers experimented with different materials, usually preferring steel, brick, tile, and concrete because of their fireproof qualities. Steel elevators were difficult to design with adequate rigidity, but circular bins were much more stable than earlier square bins. In Minnesota, the Gillette-Herzog Company and the Minneapolis Steel and Machinery Company were specialists in steel fabrication. A number of the organizers and owners of these companies invested in Electric Steel, so the choice of the elevator’s material is not surprising.

Comparatively few steel elevators were constructed before concrete became the dominant material. Steel was expensive to manufacture and required skilled hands for construction. Bins made of steel were also susceptible to rust and corrosion, especially when they were not enclosed in a protective shell. Additionally, the material was a poor insulator and unable to protect grain in extreme weather conditions. In all of these respects, reinforced concrete was a superior material and it was almost universally selected for grain elevator construction after 1910, making steel grain elevators relatively rare.

Electric Steel was built at a time when steel was still in contention. After opening, the facility quickly secured contracts with major Minneapolis millers. Business expanded over the next year, leading to the construction of five new bins in 1903, followed by another five in 1906. Each of the new tanks had a capacity of 100,000 bushels, which raised the total volume of the elevator to 2.7 million bushels.In 1914, ten 800-foot-tall grain tanks with a combined capacity of 1.25 million bushels were added to the complex, bringing the total volume of the elevator to 4 million bushels and making it “the largest single terminal in the west and one of the largest in the world,” according to the Minneapolis Journal.

Demand for storage at Electric Steel continued to increase, leading to the construction of a second workhouse in 1938. The reinforced-concrete structure had a 250,000-bushel capacity and sat immediately west of the steel workhouse. The two workhouses were connected by a series of conveyor galleries. The new addition brought the total capacity of the complex to 4.2 million bushels.

While Electric Steel expanded, Minnesota’s once-dominant grain industry began to wane. By the early twenty-first century, the facility had become obsolete with no prospect for an adaptive use. It was used for grain storage until 2013, when the complex was vacated.